Why Your Replica Airgun Groups are Inconsistent: 8 Precision Factors Most UK Hobbyists Overlook

You’ve just invested £150-£400 in an officially licensed Glock 17, Walther PPQ, or Diana 34 replica. You’ve practised your stance, controlled your breathing, and perfected your trigger pull. Yet your groupings at 10 yards look like a shotgun pattern instead of the tight cluster you expected. Before you blame your marksmanship or return your airgun, read this.

Inconsistent groupings are the number one frustration for UK replica airgun owners, and in 80% of cases, the problem isn’t your shooting technique—it’s overlooked technical factors in your equipment, ammunition, or environment that even experienced hobbyists miss. These airgun accuracy problems stem from specific, diagnosable causes that you can identify and fix systematically.

This diagnostic guide reveals the 8 precision factors that most directly impact replica airgun accuracy, complete with specific tests to identify your issue and proven solutions that UK hobbyists can implement immediately. You’ll learn how pellet selection, CO2 temperature, barrel condition, scope mounting, hold technique, environmental factors, power consistency, and maintenance intervals each affect your groups—plus exactly how to diagnose and fix each issue.

Stop wasting money on random upgrades and start targeting the actual limiting factors preventing your replica from delivering the precision you invested in achieving.

Understanding What ‘Inconsistent Groupings’ Actually Reveals

Before diving into solutions, you need to understand what your grouping patterns are telling you. Most UK hobbyists focus solely on group size, but the pattern and behaviour of your groups provide crucial diagnostic information about which precision factors need attention.

The Three Grouping Patterns and What They Mean

Scattered groups with no discernible pattern typically indicate fundamental ammunition or equipment issues. If your five shots at 10 yards land randomly within a 6-inch circle, you’re dealing with pellet-to-barrel mismatching, damaged rifling, or severely worn components. This pattern suggests your replica airgun accuracy issues stem from the ammunition or barrel system rather than external factors.

Consistent groups that shoot to the same point but are offset from your aim point indicate scope or sight alignment problems. When you can reliably place five shots within a 2-inch circle, but that entire circle sits 4 inches left and 2 inches low from where you’re aiming, your fundamental accuracy is sound—you just need to adjust your sighting system or check for mounting issues.

Groups that shift location between shooting sessions point to environmental variables or power source inconsistencies. If your Monday session produces tight groups 3 inches high and right, but Wednesday’s identical setup groups 2 inches low and left, you’re experiencing the effects of temperature, ammunition storage, or mechanical variables that change between sessions.

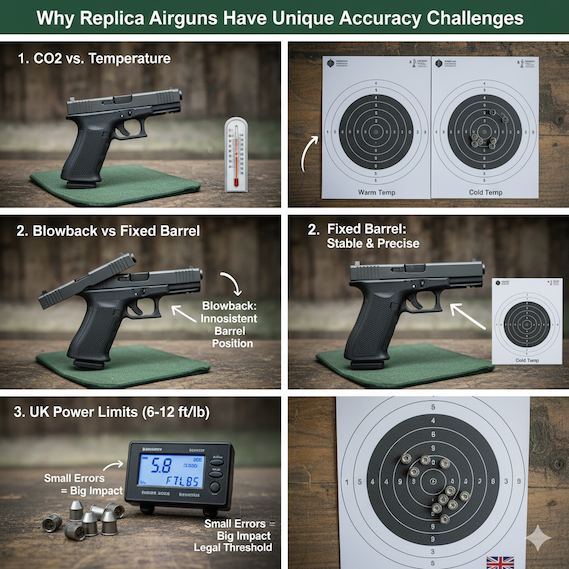

Why Replica Airguns Have Unique Accuracy Challenges

Replica airguns face precision challenges that don’t affect traditional sporting airguns, making airgun accuracy problems more complex to diagnose. CO2-powered replicas like the Umarex Glock 17 Gen5 experience temperature-dependent power variations that springer airguns avoid entirely. When ambient temperature drops significantly—typical UK weather variation—CO2 velocity can drop substantially, directly affecting your grouping size and point of impact.

Blowback mechanisms introduce additional variables versus fixed-barrel designs. Each shot cycles the slide, potentially introducing slight variations in barrel return-to-battery position that accumulate into larger group sizes over a string of shots. The Webley Alecto PCP, by contrast, maintains consistent barrel position shot after shot.

UK legal power limits create another unique challenge. With pistol replicas capped at 6 ft/lb and rifles at 12 ft/lb, you’re working with less kinetic energy margin for error. Small inconsistencies in pellet weight, power source pressure, or environmental conditions that might be negligible in higher-powered airguns become significant factors affecting precision when you’re operating at the legal threshold.

Understanding these replica-specific challenges helps you focus your diagnostic efforts on the factors most likely to affect your particular airgun type and shooting conditions.

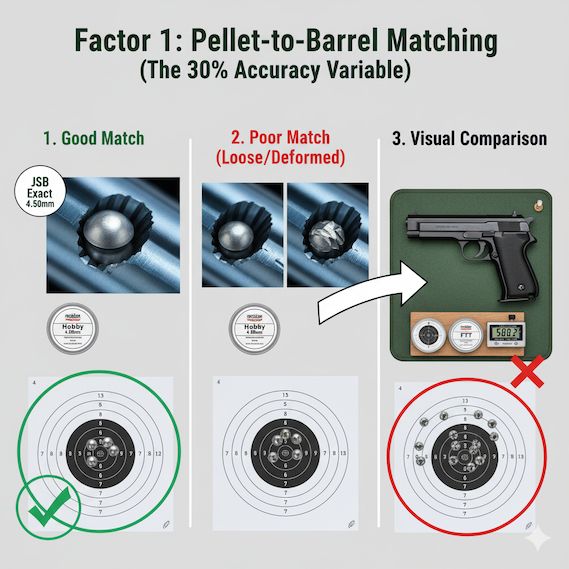

Factor 1: Pellet-to-Barrel Matching (The 30% Accuracy Variable)

The single biggest controllable factor in replica airgun accuracy isn’t your shooting technique—it’s whether your pellets properly match your barrel’s unique characteristics. Each replica airgun barrel has been machined with specific rifling dimensions that perform optimally with certain pellet head sizes and weights, regardless of brand reputation or price.

Why Premium Pellets Don’t Guarantee Accuracy

Your Walther CP88’s barrel might have been cut with rifling that grips 4.50mm pellet heads perfectly whilst allowing 4.48mm pellets to slip slightly, creating inconsistent spin and larger groups. The same barrel might perform dramatically differently with 7.9-grain RWS Hobby pellets versus 10.5-grain JSB Exact pellets, even though both are premium .177 calibre ammunition.

UK hobbyists often select pellets based on online reviews or brand reputation rather than systematic testing with their specific airgun. This approach wastes money and perpetuates airgun accuracy problems that could be solved with a £15 pellet testing investment. A controlled test comparing the same Walther CP88 might show dramatically different group sizes between different pellet types at 10 yards—identical shooting conditions, vastly different results based purely on pellet-to-barrel matching.

The physics are straightforward: your barrel’s rifling was cut to specific dimensions during manufacturing. Pellets that closely match those dimensions engage the rifling consistently, producing stable spin and predictable flight paths. Mismatched pellets either slip through the rifling (losing spin) or deform excessively (creating drag variations), both of which open up your groups significantly.

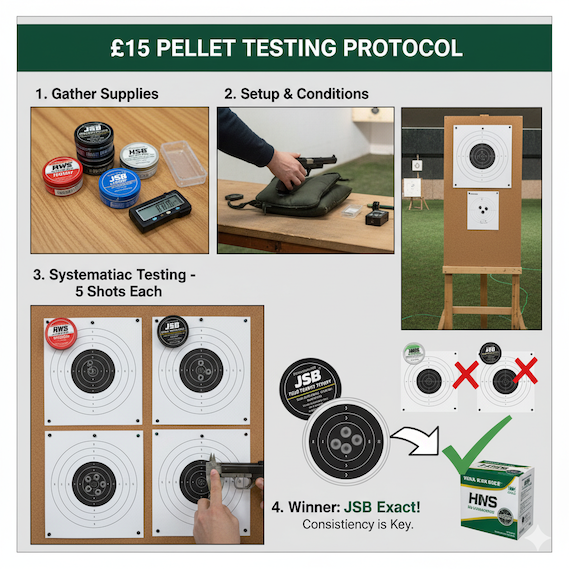

The £15 Pellet Testing Protocol

Here’s the systematic approach that improves airgun groupings more reliably than any other single intervention: Purchase sample tins of four different pellet types in your calibre—typically RWS Hobby, JSB Exact, H&N Field Target Trophy, and one wadcutter design for comparison.

Set up at your standard shooting distance: 10 yards for pistol replicas, 25 yards for rifle replicas. Using identical shooting conditions (same rest, same hold, same environmental conditions), fire controlled five-shot groups with each pellet type. Measure the groups centre-to-centre and document which pellet delivers the tightest groupings in YOUR specific airgun.

Don’t assume the most expensive pellets will perform best. Some replica barrels prefer lighter, less expensive pellets like RWS Hobby, whilst others group better with premium match pellets. The only way to determine your barrel’s preference is through systematic testing, not price point or marketing claims.

Once you’ve identified your best-performing pellet, purchase it in bulk and stick with it for all precision shooting. Switching between pellet types session to session reintroduces variables that prevent you from developing consistent technique and identifying other limiting factors in your accuracy chain.

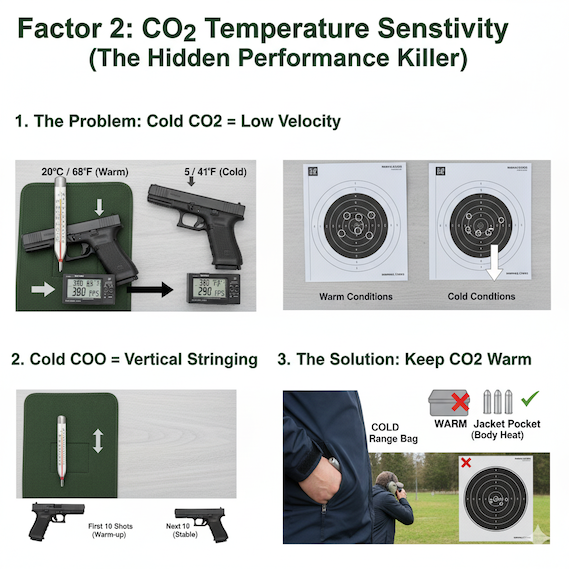

Factor 2: CO2 Temperature Sensitivity (The Hidden Performance Killer)

If you own a CO2-powered replica and shoot in UK weather conditions, temperature sensitivity is likely affecting your groups more than any other single factor. Understanding this relationship is crucial for solving CO2 pistol accuracy UK problems that frustrate hobbyists year-round.

Why Your Groups Open Up in Winter

CO2 cartridges lose velocity as temperature decreases below optimal operating conditions. This isn’t a minor inconvenience—it’s a fundamental physics limitation that directly impacts replica airgun accuracy. Your Umarex Glock 17 that performs consistently at comfortable room temperature will show reduced performance when shooting in your unheated garage during typical UK winter conditions.

Cold CO2 creates inconsistent shot-to-shot velocity because the liquid CO2 inside the cartridge vaporises less efficiently at lower temperatures. Instead of getting consistent gas pressure for each shot, you experience declining pressure throughout the shot string, creating vertical stringing in your groups that no amount of technique improvement can overcome.

This velocity inconsistency translates directly to vertical dispersion in your groups, often substantially increasing your group size compared to temperature-controlled conditions. The same CO2 cartridge that delivers minimal velocity variation indoors might show much greater variation outdoors in typical UK winter weather.

The problem compounds when you factor in the UK’s variable weather. Your groups might look excellent during a warm afternoon session, then appear terrible the next morning when temperatures have dropped overnight—leading you to question your technique or equipment when the real culprit is thermodynamics.

The CO2 Consistency Solution

Store CO2 cartridges at room temperature before shooting sessions, allowing them to stabilise for at least 30 minutes in indoor conditions before installation. Keep spare cartridges in your inside jacket pocket during outdoor shooting sessions, transferring them to the heated environment of your clothing rather than leaving them in a cold range bag.

For serious precision work in UK climate conditions, consider upgrading to PCP replicas that eliminate temperature-dependent power source variables entirely. PCP systems maintain consistent pressure regardless of ambient temperature, delivering the shot-to-shot consistency required for precision groupings year-round.

When you must shoot with CO2 in cold conditions, allow extra shots for the cartridge to reach operating temperature and expect your first 5-10 shots to group differently than shots 15-25. Factor this into your shooting sessions by using the first shots as barrel warmers rather than precision shots for group measurement.

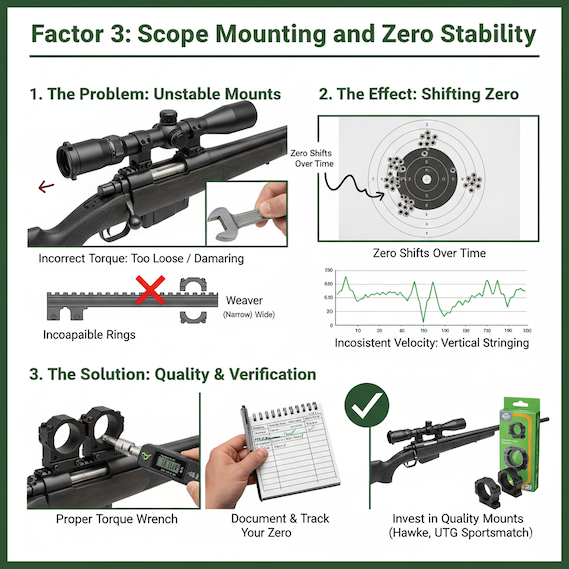

Factor 3: Scope Mounting and Zero Stability

Quality optics on poor mounts create more airgun accuracy problems than poor optics on quality mounts. Even experienced UK hobbyists often overlook mounting fundamentals that cause gradual zero shift and inconsistent groupings over time.

The £5 Component That Ruins £200 Optics

Budget scope rings create movement under recoil, even on low-powered airguns. These inexpensive components flex and shift microscopically with each shot, gradually walking your zero away from your intended point of impact. The movement might be imperceptible shot-to-shot, but over 20-30 rounds, your groups will show the cumulative effect of an unstable mounting system.

Weaver versus Picatinny rail compatibility issues cause another common source of mounting problems. Weaver rails (narrower) and Picatinny rails (wider) require different ring designs, and using incompatible rings creates play in the system that shows up as inconsistent groupings. Always verify your rail type and match rings accordingly.

Proper torque specifications prevent both under-tightening (allowing movement) and over-tightening (crushing scope tubes). Ring screws typically require specific torque values—tight enough to prevent movement but not so tight that you damage the scope tube. Most hobbyists either finger-tighten (insufficient) or over-torque with standard tools (damaging).

The 50-Shot Zero Verification Test

After mounting any new optic, check your zero every 50 shots during the first 200 rounds. This identifies mounting issues before they become ingrained in your technique. Re-tighten mounting screws after your first 20 shots to account for initial settling—materials compress slightly under use, and screws that felt tight initially may need adjustment.

Invest in quality mounts from reputable manufacturers rather than the rings included with budget scopes. Brands like Hawke, UTG, and Sportsmatch deliver the mechanical precision required for consistent groupings, and their modest cost compared to your total optics investment provides significant accuracy dividends.

Document your zero position and group sizes after mounting system changes. This creates baseline data that helps you identify whether subsequent accuracy issues stem from mounting problems versus other factors in your precision chain.

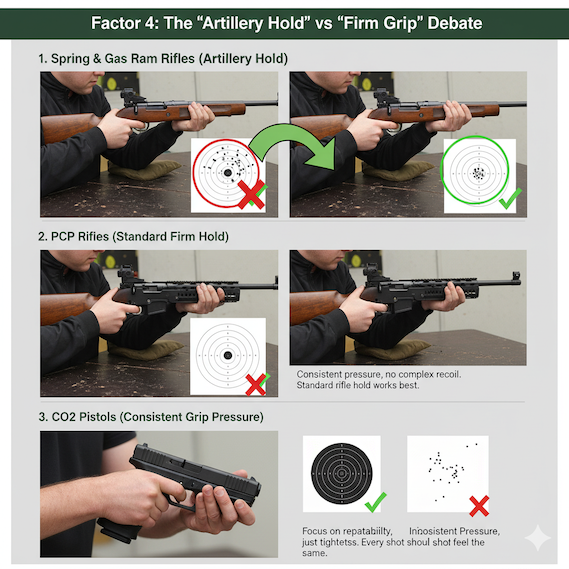

Factor 4: The ‘Artillery Hold’ vs ‘Firm Grip’ Debate

Hold technique represents one of the most misunderstood aspects of replica airgun accuracy, particularly for UK hobbyists transitioning from rimfire shooting experience. The counterintuitive physics of spring airgun recoil require techniques that feel wrong but deliver measurably better groups.

Why Your Rifle Shooting Technique Fails on Spring Airguns

Spring-piston airguns like the Diana 34 or Weihrauch HW80 recoil forward before recoiling backward—the exact opposite of firearms. When you pull the trigger, the piston slams forward, pushing the rifle forward against your hold before spring compression generates the backward recoil familiar from rimfire shooting.

A tight “death grip” prevents this natural recoil pattern, changing barrel harmonics and shifting your point of impact unpredictably. The barrel wants to vibrate in a specific pattern during the firing cycle, and rigid restraint alters those vibrations enough to open up groups significantly. Testing demonstrates substantial group improvement when switching from a rigid hold to the proper artillery hold technique.

The artillery hold allows repeatable barrel movement by providing consistent support without rigid restraint. Your non-trigger hand supports the forend with loose contact, allowing the rifle to recoil naturally whilst maintaining repeatable contact points. This feels unstable compared to firm rifle holds, but produces measurably tighter groups with spring-powered replicas.

Which Hold for Which Replica Type

Spring and gas ram rifles require the artillery hold for optimal accuracy. Any Diana, Weihrauch, or BSA spring rifle will group better with loose, consistent support than with rigid restraint. Practise the technique until it feels natural—it’s counterintuitive but mechanically correct for these powerplant types.

PCP rifles perform well with standard firm holds because they don’t produce the forward-then-backward recoil pattern of springer mechanisms. You can apply familiar rifle shooting techniques without the special considerations required for spring powerplants.

CO2 pistols benefit most from consistent grip pressure rather than necessarily tight grip pressure. Find a grip firmness that you can repeat identically shot after shot, whether that’s firm or moderate. Consistency matters more than absolute grip strength for CO2 pistol accuracy UK performance.

Practise your hold technique with dry-firing sessions to develop muscle memory without ammunition costs. Once you’ve established the proper feel, confirm with live-fire testing that your groups tighten with correct technique application.

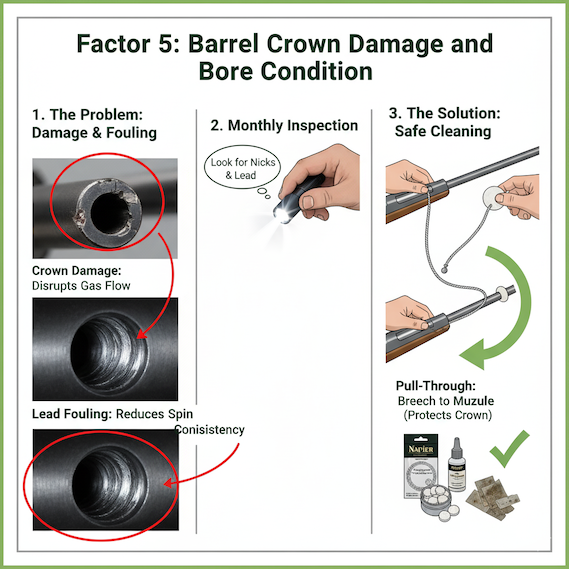

Factor 5: Barrel Crown Damage and Bore Condition

Physical damage to your barrel crown or bore condition represents a hidden cause of airgun accuracy problems that gradually worsens over time. Unlike sudden failures, barrel condition deteriorates slowly enough that many UK hobbyists adapt their expectations rather than recognising the degradation.

The Inspection You Should Do Monthly

Crown damage—nicks, dents, or irregularities at the muzzle—disrupts gas flow around the pellet as it exits the barrel, causing pellet instability and inconsistent flight paths. Even minor crown damage invisible to casual inspection can open groups significantly because the crown represents the last point where gas flow can influence pellet flight.

Lead fouling accumulates in rifling grooves, especially with softer pellets, gradually reducing the barrel’s ability to impart consistent spin. This fouling build-up is nearly invisible but shows up as gradually opening groups over hundreds of shots. Visual inspection with a bright torch reveals lead deposits that appear as bright streaks in the rifling grooves.

Conduct monthly inspections using a household LED torch to examine your barrel crown and rifling condition. Look for chips or irregularities around the muzzle edge and bright lead streaks in the rifling. Pull-through cleaning every 300-500 shots maintains accuracy by removing accumulated fouling before it affects precision.

UK-Compliant Cleaning Without Gunsmith Tools

Pull-through cord systems from manufacturers like Napier and VFG work safely for UK hobbyists without requiring firearms cleaning experience or specialised tools. These systems clean from breech to muzzle, avoiding crown damage that can result from improper rod cleaning techniques.

Avoid over-cleaning, which causes more problems than it solves. Spring airguns typically need cleaning every 500 shots, whilst CO2 replicas might extend to 750-1000 shots between cleanings. PCP systems generally run cleanest and require the least frequent maintenance.

Stock appropriate cleaning supplies including proper calibre pull-throughs, cleaning patches, and light pellet lubricant. Proper maintenance costs far less than replacement barrels and prevents accuracy degradation that develops gradually over hundreds of shots.

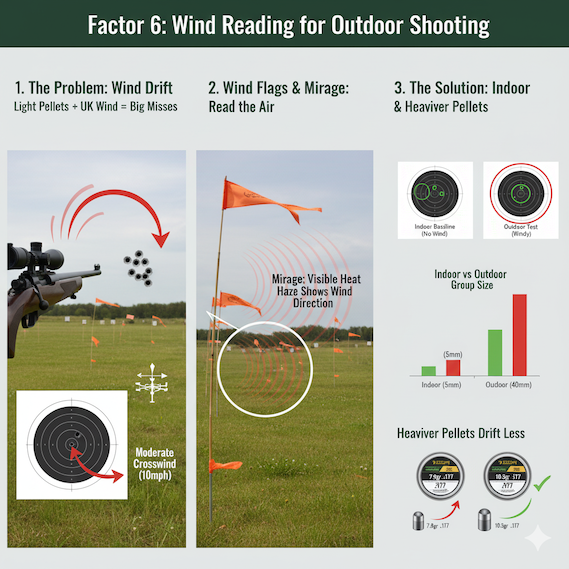

Factor 6: Wind Reading for Outdoor Shooting

Environmental awareness separates casual shooters from precision hobbyists, particularly when shooting outdoors in variable UK weather conditions. Wind affects lightweight airgun pellets more dramatically than most hobbyists realise, often masquerading as airgun accuracy problems when the real issue is environmental.

Why UK Weather Affects Airguns More Than You Think

Lightweight .177 pellets weighing 7-8 grains drift significantly in even moderate crosswinds common throughout the UK. At 25 yards, moderate crosswinds can move a standard pellet several inches horizontally—larger than the group size you’re trying to achieve. This wind drift often exceeds the precision capabilities of your equipment, making environmental conditions the limiting factor rather than mechanical accuracy.

UK weather patterns create constantly changing wind conditions that affect consecutive shots differently. What appears to be replica airgun accuracy problems might actually be your groups responding normally to shifting wind patterns that you haven’t learned to read and compensate for during your shooting session.

Mirage, visible heat shimmer rising from sun-warmed surfaces, provides wind direction and intensity information that experienced shooters use to time their shots. Learning to read these natural wind indicators transforms outdoor accuracy performance more than most equipment upgrades.

The Indoor Baseline Test

Shoot 20-round baseline groups indoors to establish your equipment’s actual capability without environmental variables. This indoor baseline represents your theoretical best performance and provides comparison data for outdoor shooting sessions. When your outdoor groups measure significantly larger than indoor groups, environmental factors rather than equipment limitations are constraining your precision.

Compare indoor versus outdoor group measurements to isolate wind effects from equipment issues. If your indoor groups measure substantially smaller than outdoor groups under identical shooting conditions, you’re seeing environmental influence rather than airgun accuracy problems requiring equipment solutions.

Use this baseline data to determine whether you need heavier pellets for outdoor shooting conditions. Heavier pellets drift less in crosswinds, and upgrading from 7.9-grain to 10.3-grain pellets might tighten your outdoor groups significantly whilst maintaining indoor performance.

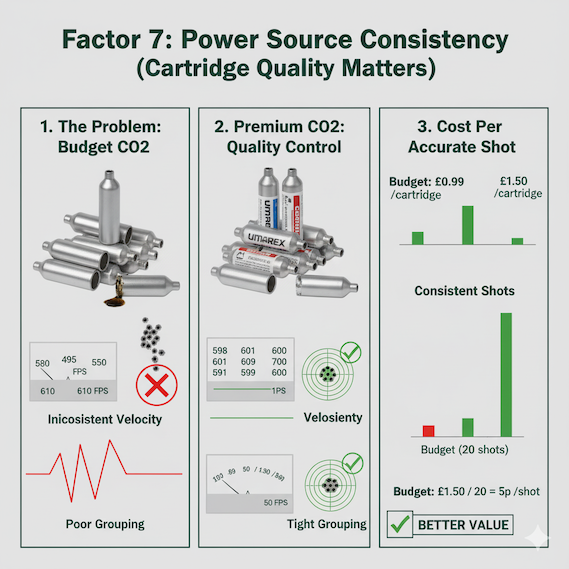

Factor 7: Power Source Consistency (Cartridge Quality Matters)

Quality differences in CO2 cartridges create measurable impact on precision that most UK hobbyists overlook when troubleshooting airgun accuracy problems. The lowest-cost solution often proves most expensive when calculated per accurate shot delivered.

Why Budget CO2 Cartridges Cost You Accuracy

Fill weight variance in budget cartridges can range significantly compared to consistent fill weights in premium cartridges. This weight variation translates directly to velocity inconsistency that opens up your groups measurably. Quality testing shows budget cartridges delivering substantially greater velocity variation compared to premium cartridges.

Oil contamination in low-quality cartridges affects valve sealing and shot count consistency. Contaminated cartridges deliver fewer consistent shots before pressure drops below optimal operating range, forcing you to change cartridges more frequently and losing zero stability between cartridge changes.

Premium brands like Umarex, ASG, and Crosman deliver measurably more consistent performance through tighter manufacturing tolerances and quality control processes. The velocity consistency improvement alone justifies their modest price premium for precision shooting applications.

The Cost-Per-Accurate-Shot Calculation

Premium cartridges cost approximately 50p more than budget alternatives but deliver tighter groups and more consistent shots per cartridge. When you calculate cost per accurate shot rather than cost per cartridge, premium CO2 represents better value for serious precision work.

False economy of budget cartridges becomes apparent when you’re developing precision skills that require consistent equipment performance. Trying to improve airgun groupings with inconsistent power sources wastes practice time and creates frustration that quality cartridges eliminate.

Stock reliable cartridges from tested suppliers rather than purchasing the cheapest available options. Consistent power sources allow you to focus on technique development and other precision factors without second-guessing whether your power source is contributing to accuracy inconsistency.

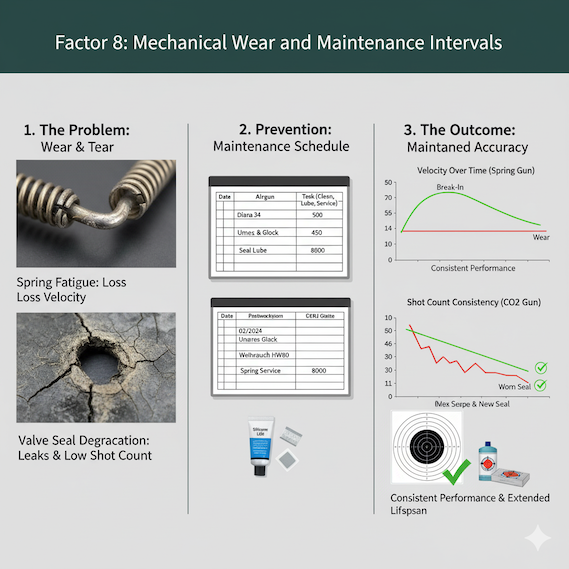

Factor 8: Mechanical Wear and Maintenance Intervals

Understanding realistic expectations for replica airgun longevity helps you identify when accuracy degradation stems from normal wear versus correctable factors. Mechanical components wear predictably, and recognising wear patterns prevents wasted troubleshooting time.

When ‘Breaking In’ Becomes ‘Wearing Out’

Spring airguns improve accuracy over the first 200 shots as springs settle and components mate properly, then maintain consistent performance for thousands of shots before gradual accuracy decline from spring fatigue. CO2 pistol valve seals deteriorate with use, showing up as declining velocity and shot count before affecting accuracy directly.

PCP rifles maintain consistency longest due to lower operating stresses, but require periodic seal service depending on usage patterns. Understanding these lifespan expectations helps you distinguish between normal wear and correctable airgun accuracy problems.

Recognition of wear symptoms prevents frustration when equipment reaches normal service intervals. Velocity decline, reduced shot count, or gradually opening groups after extensive use indicate normal wear rather than sudden failure requiring immediate attention.

The Preventive Maintenance Schedule

Visual inspection and basic cleaning every 300-500 shots prevents most accuracy degradation from preventable causes. Seal lubrication for CO2 replicas every 1,000 shots or six months maintains consistent performance and extends component life significantly.

Professional service or spring replacement for spring rifles after extensive use restores original accuracy and prevents accuracy deterioration from becoming severe enough to affect shooting enjoyment. Preventive maintenance costs less than component replacement after failure.

Document maintenance intervals and accuracy performance to identify patterns in your specific equipment. Some replicas require more frequent attention whilst others exceed normal service intervals, and tracking performance helps you optimise maintenance scheduling for your shooting volume.

Your 30-Day Accuracy Improvement Action Plan

Rather than randomly trying different solutions, follow this systematic troubleshooting sequence to identify and fix your specific airgun accuracy problems efficiently. This diagnostic approach saves money by targeting actual limiting factors rather than perceived problems.

Week 1-2: Isolate Equipment Variables

Conduct indoor pellet testing with four different pellet types to eliminate ammunition variables from your accuracy equation. Purchase sample tins of RWS Hobby, JSB Exact, H&N Field Target Trophy, and one wadcutter design. Shoot controlled five-shot groups with each type using identical conditions and document which pellet delivers the tightest groupings with your specific airgun.

Verify scope mounting integrity and re-zero using your best-performing pellet. Check ring specifications and ensure your mounting system eliminates movement variables that can masquerade as ammunition or technique problems. Document your zero position and group sizes for baseline comparison.

Establish your equipment’s actual baseline capability in controlled indoor conditions. This eliminates environmental variables and provides reference data for comparing outdoor performance and diagnosing whether problems stem from equipment or environmental factors.

Week 3-4: Optimise Technique and Environment

Practise proper hold technique with 50-shot sessions focusing on consistency rather than group size initially. If shooting a spring rifle, develop artillery hold muscle memory through dry-fire practice before confirming technique improvement with live ammunition. CO2 pistol shooters should focus on repeatable grip consistency.

Compare indoor versus outdoor group measurements to quantify environmental impact on your replica airgun accuracy. If outdoor groups measure significantly larger than indoor groups, focus on wind reading skills and consider heavier pellets for outdoor shooting rather than equipment modifications.

Implement CO2 temperature management if shooting outdoors in UK weather conditions. Store cartridges at room temperature and keep spares warm during cold shooting sessions. Document performance differences between temperature-controlled and ambient temperature shooting.

Beyond 30 Days: Targeted Upgrades

Now you have diagnostic data showing whether barrel condition, power source quality, mounting systems, or other components represent your accuracy limiting factors. Invest in specific solutions based on your identified constraints rather than general upgrades that might not address your actual problems.

Browse precision accessories with confidence knowing what your setup actually needs for performance improvement. Whether that’s premium pellets, quality scope rings, better CO2 cartridges, or maintenance supplies, your testing data guides investment decisions toward solutions that deliver measurable results.

Continue systematic testing whenever you modify components, maintaining documentation that helps you understand which changes improve performance versus which changes waste money without accuracy benefits.

Conclusion

Inconsistent replica airgun groups are rarely about marksmanship—they’re diagnostic indicators pointing to specific equipment, ammunition, or environmental factors that you can identify and fix systematically. The eight precision factors covered here affect every UK hobbyist’s accuracy, but most remain hidden because shooters focus on technique rather than systematic troubleshooting.

By working through the diagnostic sequence methodically, you’ll identify YOUR specific limiting factor and implement targeted solutions that deliver measurable accuracy improvements within 30 days. Start with the £15 pellet testing protocol this weekend, establish your baseline capabilities, then work through each factor until you’ve eliminated the variables preventing consistent groupings.

Your investment in quality replica airguns deserves systematic precision development rather than random upgrade purchases. Focus on diagnosing actual problems rather than perceived problems, and you’ll achieve the consistent accuracy that justified your equipment investment in the first place.

Stop accepting inconsistent performance from equipment capable of precision shooting. These eight factors provide the roadmap to unlock your replica’s true accuracy potential—but only if you commit to systematic diagnosis rather than hopeful guesswork.