PCP Air Rifle Mastery: Engineering Precision for UK Target Shooters Who Demand Professional Results

At 50 yards, your springer delivers 2-inch groups on a good day. A properly tuned PCP air rifle UK system? Consistent half-inch groups, shot after shot, regardless of ambient temperature or how tired your shoulder gets. For UK target shooters who’ve hit the accuracy ceiling with spring-piston technology, Pre-Charged Pneumatic systems represent a fundamental leap in precision engineering—but only if you understand the technical principles that separate professional-grade performance from expensive disappointment.

The UK airgun market is flooded with PCP marketing claims about shot counts, fill pressures, and power outputs, yet serious shooters struggle to find technically accurate information explaining how these systems actually deliver consistency. Without understanding regulator behaviour, barrel harmonics, and pneumatic dynamics, you’re making equipment decisions worth hundreds of pounds based on incomplete information.

This comprehensive guide delivers the engineering knowledge UK precision shooters need to master PCP air rifle technology. You’ll understand exactly how PCP systems achieve superior consistency, which technical specifications actually matter for PCP air rifle accuracy, and how to optimise performance through proper setup and maintenance. Whether you’re evaluating your first PCP purchase or fine-tuning an existing system, this is the technical foundation serious shooters need.

We’ll explore PCP pneumatic engineering from reservoir dynamics to valve timing, examine real-world performance data that reveals which specifications impact accuracy, provide practical optimisation techniques for barrel harmonics and ammunition matching, establish comprehensive maintenance protocols, and clarify UK air rifle laws. By the end, you’ll have the technical mastery to make informed equipment decisions and extract maximum precision from PCP technology.

PCP Engineering Fundamentals: How Pneumatic Systems Deliver Superior Consistency

The superiority of pre-charged pneumatic systems over spring-piston technology lies in fundamental physics differences that eliminate the primary causes of shot-to-shot variation. Understanding these engineering principles is essential for serious UK precision shooters who demand professional-grade results.

The Physics of Pre-Charged Pneumatics: Pressure, Volume, and Projectile Acceleration

PCP air rifles store compressed air at 200-250 BAR (approximately 3,000-3,600 PSI) in high-pressure reservoirs, creating a fundamentally different energy delivery system compared to spring compression cycles. When the trigger releases the firing valve, this stored compressed air expands rapidly behind the pellet, providing consistent energy release that eliminates the velocity variations plaguing springer accuracy.

The relationship between air reservoir pressure, volume, and shot count reveals critical engineering trade-offs that affect long-term consistency. A larger reservoir volume provides more total stored air, enabling higher shot counts at consistent velocities. However, larger reservoirs add weight and bulk—factors that matter for field shooting applications. The engineering sweet spot for most UK target shooters lies in reservoirs providing 80-120 consistent shots within a 20 FPS velocity spread, maintaining accuracy whilst providing practical shot counts for extended shooting sessions.

Most importantly, PCP systems eliminate the recoil and lock-time variables that destroy springer precision. Spring-piston rifles generate significant rearward recoil as the piston compresses air, followed by forward recoil as the spring decompresses—creating a complex vibration pattern that affects pellet exit timing and point-of-impact consistency. PCP systems produce virtually no recoil, allowing shooters to maintain perfect sight picture throughout the firing cycle and eliminating the technique-dependent accuracy variables that plague springer shooters.

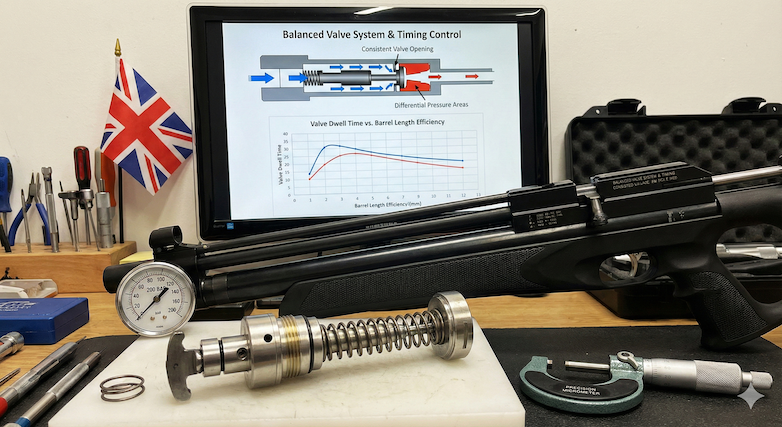

Valve Design and Timing: The Heart of Shot-to-Shot Consistency

The firing valve represents the critical control point for shot-to-shot consistency in PCP systems. Valve opening duration and airflow dynamics directly control projectile velocity consistency, making valve design the primary factor determining whether a PCP rifle delivers professional-grade accuracy or frustrating variations.

Balanced valve systems utilise differential pressure areas to reduce hammer strike force requirements, creating more controlled valve opening characteristics. When designed properly, balanced valves open with consistent timing and duration regardless of reservoir pressure variations, maintaining velocity consistency throughout the pressure curve. This engineering approach explains why some budget PCP rifles with balanced valve designs can outperform more expensive rifles with poorly designed hammer-strike systems.

The critical relationship between valve timing and barrel length reveals why PCP rifles cannot simply be optimised by increasing air pressure. Optimal valve dwell time—the duration the valve remains open—must match barrel length and projectile weight to achieve maximum efficiency. Too short a dwell time wastes air pressure and reduces velocity consistency. Too long a dwell time creates turbulence behind the projectile, degrading accuracy and wasting air. Properly engineered PCP systems calculate this relationship precisely, explaining why specific barrel lengths work optimally with particular valve designs.

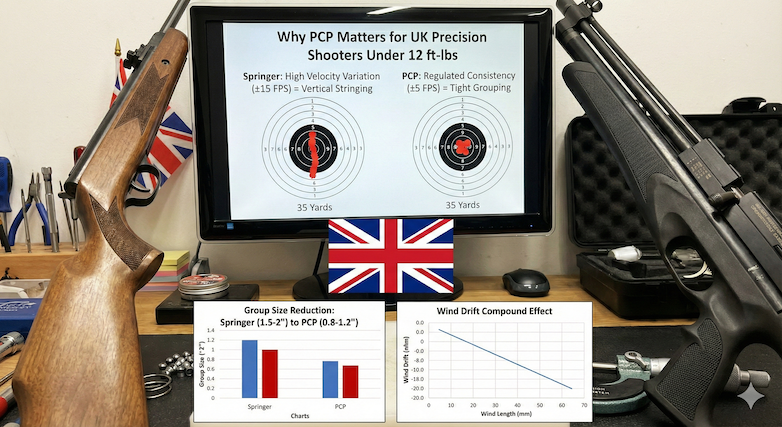

Why PCP Technology Matters for UK Precision Shooters Under 12 ft-lbs

UK legal power limits create unique advantages for PCP air rifle technology that many shooters don’t fully appreciate. The 12 ft-lb muzzle energy limit means consistency matters far more than raw power for achieving tight groups, and PCP systems excel at delivering repeatable energy output within this constraint.

At sub-12 ft-lb energy levels, even small velocity variations create measurable accuracy degradation at typical UK shooting distances of 25-50 yards. A springer rifle producing ±15 FPS velocity spread will show noticeable vertical stringing at these distances, whilst a well-tuned regulated PCP rifle maintaining ±5 FPS consistency keeps pellets in the same horizontal plane. This consistency advantage becomes even more pronounced in windy conditions, where velocity variations compound with wind drift to open groups significantly.

Real-world accuracy improvements when transitioning from quality springer to PCP platforms typically show group size reductions of 40-60% at 35 yards under similar shooting conditions. A springer delivering 1.5-2 inch groups often improves to 0.8-1.2 inch groups with proper PCP selection and setup, representing the difference between frustrating near-misses and confident precision on small targets.

Regulator Technology: The Foundation of Professional-Grade PCP Performance

Regulated PCP rifles represent the pinnacle of pneumatic consistency engineering, providing the stable pressure foundation necessary for professional-grade accuracy. Understanding regulator operation and specifications enables informed decisions about equipment investments that deliver measurable performance improvements.

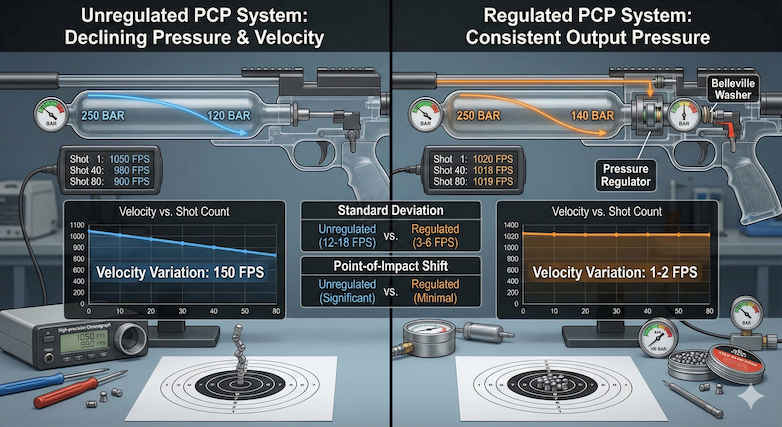

Regulated vs Unregulated Systems: Engineering Trade-Offs and Performance Data

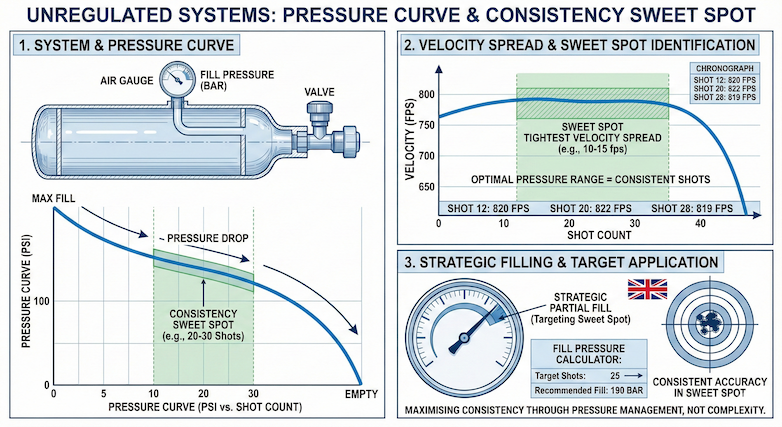

Unregulated PCP systems exhibit velocity curves that start high with full reservoir pressure and gradually decline as air pressure drops, creating systematic accuracy degradation across shot strings. Chronograph testing of quality unregulated rifles typically shows initial velocities 30-50 FPS higher than end-of-string velocities over 80-shot sequences, with corresponding point-of-impact shifts that open groups significantly.

Regulator operation centres on pressure reduction valves that maintain consistent output pressure regardless of reservoir pressure variations. The regulator’s internal poppet valve opens and closes rapidly to maintain set output pressure, creating a plateau of consistent performance across the majority of available shots. Quality regulators maintain output pressure within ±2-3 PSI across 60-80 shots, compared to unregulated pressure drops of 80-120 PSI over similar shot counts.

Real chronograph data comparing regulated vs unregulated systems reveals the practical accuracy impact. Unregulated rifles often show standard deviations of 12-18 FPS across full shot strings, whilst regulated systems typically maintain 3-6 FPS standard deviations across their regulated shot count. This consistency translates directly to tighter groups and more predictable point-of-impact, especially at longer ranges where velocity variations become increasingly significant.

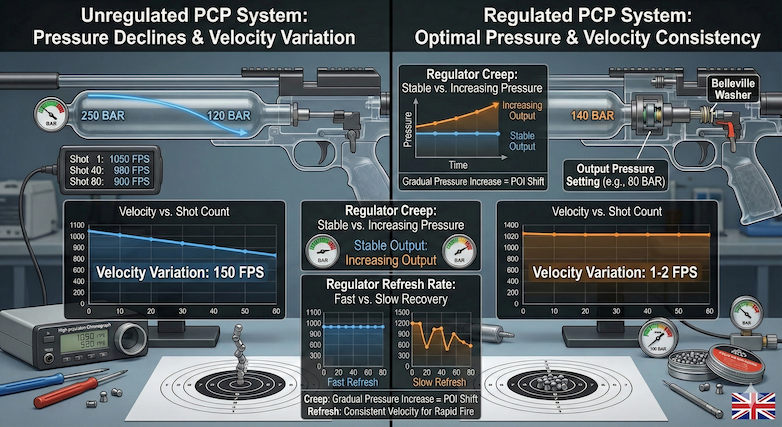

Regulator Specifications That Actually Matter for Consistency

Output pressure settings represent the primary specification affecting both velocity consistency and shot count in regulated systems. Lower output pressures extend shot count but may reduce maximum velocity potential, whilst higher pressures provide more energy but consume air faster. The engineering sweet spot for most UK applications lies in output pressures providing optimal velocity with 60-80 consistent shots—sufficient for extended shooting sessions without requiring frequent refills.

Regulator creep and lock-up issues plague poorly designed or worn regulators, gradually increasing output pressure over time and destroying the consistency that justifies regulator investment. Quality regulators maintain stable output pressure for thousands of shots, whilst budget regulators may show measurable creep within hundreds of shots. Symptoms include gradually increasing velocities, point-of-impact shifts during shooting sessions, and reduced shot counts as the regulator slowly increases pressure beyond optimal settings.

The relationship between regulator refresh rate and firing cadence matters for competition shooters who fire rapid strings. Some regulators require brief pauses between shots to fully refresh output pressure, whilst others handle rapid-fire sequences without pressure variations. Understanding your regulator’s refresh characteristics enables shooting techniques that maximise consistency during timed competitions.

When Unregulated Systems Make Sense: Engineering Context for Different Shooting Disciplines

Despite regulator advantages, unregulated systems offer engineering benefits for specific UK shooting applications. Mechanical simplicity reduces potential failure points and maintenance requirements, making unregulated rifles attractive for field shooting where reliability outweighs absolute precision. Additionally, unregulated systems typically cost £100-200 less than equivalent regulated models, enabling access to quality PCP technology for shooters prioritising value.

Optimal pressure range identification for unregulated rifles enables working within their consistency sweet spot. Most unregulated rifles deliver their tightest velocity spreads within a specific pressure range—typically 20-30 shots in the middle portion of their pressure curve. By identifying this range through chronograph testing and limiting shooting to these pressures, skilled shooters can achieve near-regulated consistency whilst maintaining mechanical simplicity.

Fill pressure calculators help optimise unregulated performance by determining exact fill pressures that provide target shot counts within optimal pressure ranges. Rather than filling to maximum pressure and accepting the entire velocity curve, strategic partial fills can position the majority of shots within the rifle’s accuracy sweet spot, effectively creating consistency advantages without regulator complexity.

Barrel Systems and Harmonics: Extracting Maximum Accuracy from PCP Platforms

Barrel quality and harmonics management separate professional-grade PCP air rifle accuracy from mediocre performance. Understanding manufacturing methods, harmonic behaviour, and systematic optimisation techniques enables extracting maximum precision from PCP platforms.

Barrel Manufacturing Methods: Understanding Quality Differences That Impact Precision

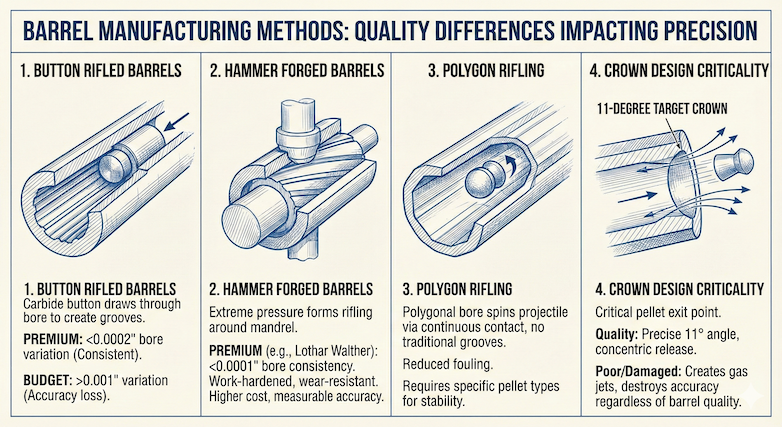

Button rifled barrels represent the most common manufacturing method for quality PCP rifles, using a precision carbide button drawn through the barrel bore to create rifling grooves. This process creates consistent rifling geometry and surface finish when properly executed, with premium button-rifled barrels showing bore diameter variations under 0.0002 inches across their length. Budget button-rifled barrels may exhibit variations exceeding 0.001 inches—differences that destroy accuracy potential regardless of other system quality.

Hammer forged barrels utilise extreme pressure to form rifling around a mandrel, creating exceptionally consistent bore dimensions and work-hardened surfaces that resist wear. Premium manufacturers like Lothar Walther and Air Arms produce hammer-forged barrels maintaining bore consistency within 0.0001 inches, explaining the accuracy advantages of rifles using these premium barrel suppliers. The manufacturing cost premium for hammer-forged barrels typically adds £100-150 to rifle retail prices but delivers measurable accuracy improvements.

Polygon rifling systems eliminate traditional rifling grooves in favour of slightly twisted polygonal bore shapes that spin projectiles through continuous contact rather than groove engagement. Whilst less common in PCP applications, polygon rifling can deliver excellent accuracy with reduced lead fouling when properly executed. However, polygon barrels require specific pellet types for optimal performance and may not stabilise all ammunition weights effectively.

Crown design critically impacts accuracy regardless of barrel manufacturing quality. The crown—the barrel’s muzzle end where pellets exit—must release projectiles cleanly without gas disturbance that deflects pellets. Quality crowns feature precise 11-degree angles and perfect concentricity, whilst damaged or poorly cut crowns create accuracy-destroying gas jets that make precision impossible regardless of other system excellence.

Barrel Harmonics and Vibration Management: The Physics of Consistent Grouping

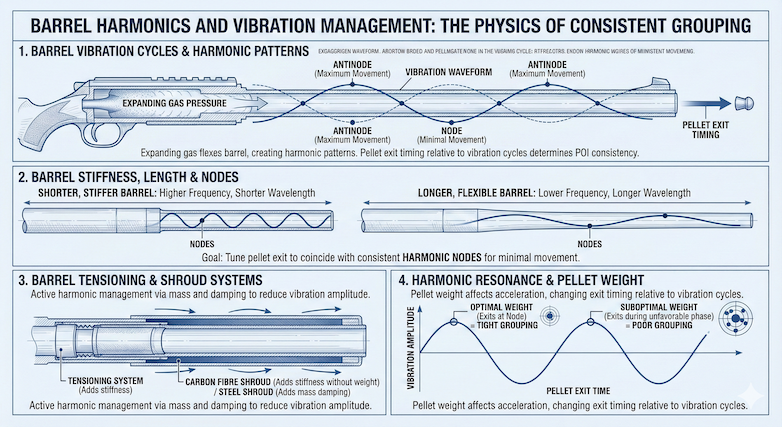

Barrel vibration cycles occur with every shot as expanding gas pressure flexes the barrel steel, creating complex harmonic patterns that affect pellet exit timing. High-speed photography reveals barrels whipping in consistent patterns during firing, with pellet exit timing relative to these vibration cycles determining point-of-impact consistency. Understanding and managing these harmonics represents advanced optimisation knowledge that separates professional-grade accuracy from amateur results.

The relationship between barrel stiffness, length, and harmonic nodes reveals why some barrel configurations naturally group better than others. Shorter, stiffer barrels exhibit higher frequency vibrations with shorter wavelengths, whilst longer, more flexible barrels show lower frequency patterns with longer wavelengths. The engineering goal involves timing pellet exit to coincide with consistent harmonic nodes where barrel movement is minimal and repeatable.

Barrel tensioning systems and shrouds actively manage harmonics by adding mass and damping to reduce vibration amplitude. Carbon fibre shrouds add stiffness without excessive weight, whilst steel shrouds provide mass damping that reduces vibration magnitude. Premium rifles often incorporate tuned shroud systems calculated to shift harmonic patterns for optimal accuracy with specific ammunition weights.

Harmonic resonance explains why certain pellet weights group significantly better than others in specific barrels. Pellet weight affects acceleration time within the barrel, changing the timing relationship between pellet exit and barrel vibration cycles. Systematic testing across pellet weight ranges often reveals specific weights that coincide with optimal harmonic nodes, delivering dramatically improved accuracy compared to weights that exit during unfavourable vibration phases.

Ammunition Matching: Systematic Testing Protocols for Finding Your Rifle’s Preferred Pellet

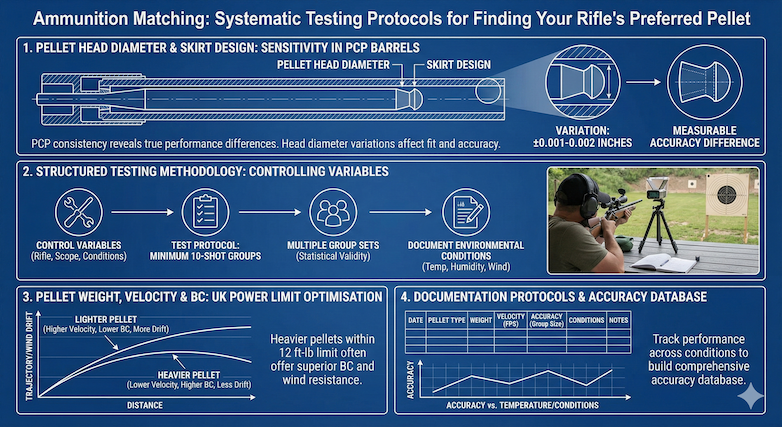

PCP barrels show particular sensitivity to pellet head diameter and skirt design due to their consistent velocity characteristics. Unlike springers where velocity variations can mask ammunition-related accuracy differences, PCP consistency reveals true ammunition performance differences. Pellet head diameters varying by 0.001-0.002 inches can show measurable accuracy differences in precision barrels, making systematic ammunition testing essential for extracting maximum accuracy.

Structured testing methodology requires controlling all variables except pellet selection to isolate true performance differences from random variation. Testing protocols should include minimum 10-shot groups at consistent distances, multiple group sets for statistical validity, and careful environmental condition documentation. Many shooters make ammunition decisions based on single 5-shot groups that may represent random variation rather than true accuracy differences.

Understanding pellet weight, velocity, and ballistic coefficient relationships within UK power limits reveals optimisation opportunities many shooters miss. Heavier pellets at lower velocities often deliver superior ballistic coefficients and wind resistance compared to lighter pellets at higher velocities within the 12 ft-lb constraint. Systematic testing across weight ranges frequently identifies heavier pellets delivering tighter groups and reduced wind sensitivity despite lower velocities.

Documentation protocols for tracking ammunition performance across environmental conditions enable building comprehensive accuracy databases that guide future ammunition selection. Factors including temperature, humidity, wind conditions, and barrel cleanliness all affect accuracy testing results. Proper documentation reveals which ammunition maintains consistency across varying conditions rather than delivering accuracy only under specific circumstances.

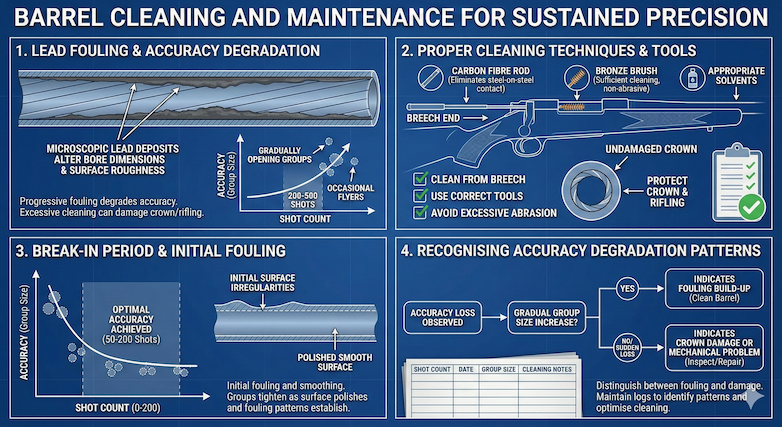

Barrel Cleaning and Maintenance for Sustained Precision

Lead fouling progressively degrades accuracy as microscopic lead deposits alter barrel bore dimensions and surface roughness. However, excessive cleaning can damage barrel crowns and rifling, making understanding proper cleaning frequency and techniques essential for maintaining long-term accuracy. Most quality PCP barrels show accuracy degradation after 200-500 shots depending on ammunition type and shooting conditions, with symptoms including gradually opening groups and occasional unexplained flyers.

Proper cleaning techniques preserve barrel crown and rifling integrity whilst removing accuracy-degrading fouling. Cleaning from the breech end prevents crown damage, whilst using appropriate solvents and brushes removes lead deposits without abrading barrel steel. Carbon fibre cleaning rods eliminate the steel-on-steel contact that can damage rifling when used properly, whilst bronze brushes provide sufficient cleaning action without excessive abrasion.

The break-in period for new barrels involves initial fouling and surface smoothing that can require 50-200 shots before achieving optimal accuracy. During break-in, groups may gradually tighten as microscopic surface irregularities polish smooth and the barrel establishes consistent fouling patterns. Understanding this process prevents premature concerns about new barrel accuracy and establishes realistic expectations for achieving optimal performance.

Recognising accuracy degradation patterns enables distinguishing between correctable maintenance issues and permanent barrel wear. Gradual group size increases typically indicate fouling build-up, whilst sudden accuracy loss may indicate crown damage or mechanical problems. Maintaining shot count and accuracy logs enables identifying degradation patterns and optimising cleaning schedules for sustained precision performance.

Complete PCP Optimisation: Advanced Setup Techniques for Competition-Level Performance

Extracting maximum accuracy from PCP air rifles requires systematic optimisation beyond basic operation. Advanced setup techniques targeting hammer spring tuning, stock bedding, and optics mounting enable competition-level performance from quality PCP platforms.

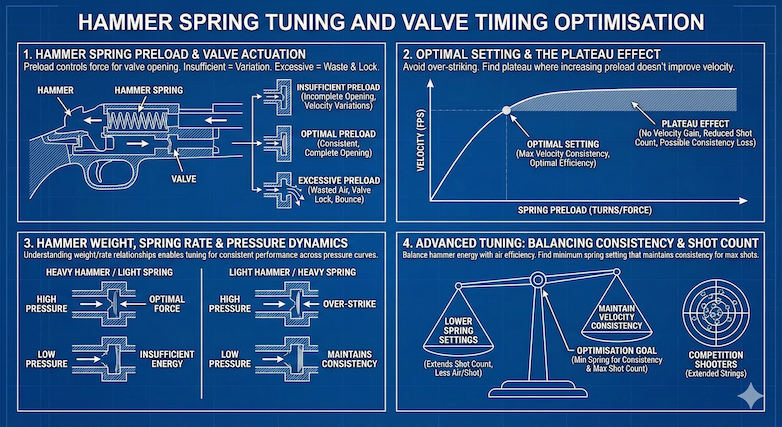

Hammer Spring Tuning and Valve Timing Optimisation

Hammer spring preload directly affects valve opening duration and shot consistency by controlling the force available for valve actuation. Insufficient preload results in incomplete valve opening and velocity variations, whilst excessive preload wastes air and may cause valve lock that prevents proper closing. The optimisation process requires systematic adjustment whilst monitoring chronograph testing results to identify settings delivering maximum velocity consistency with optimal air efficiency.

Finding the optimal hammer spring setting involves avoiding over-striking that wastes air without improving consistency. The engineering goal involves providing just sufficient force for complete, consistent valve opening without excess energy that creates valve bounce or extended dwell times. Proper optimisation typically shows a plateau effect where increasing spring preload beyond optimal settings shows no velocity increase but reduces shot count and may degrade consistency.

The relationship between hammer weight, spring rate, and valve lock at different pressures reveals why some rifles require different settings across their pressure curves. Heavy hammers with light springs may provide optimal performance at high pressures but insufficient energy at lower pressures, whilst light hammers with heavy springs may over-strike at high pressures but maintain consistency as pressure drops. Understanding these relationships enables advanced tuning for consistent performance across full shot strings.

Advanced tuning for maximum shot count whilst maintaining velocity consistency requires balancing hammer energy with air efficiency. Lower hammer spring settings typically extend shot count by reducing air consumption per shot, but may compromise velocity consistency if valve opening becomes inconsistent. The optimisation process involves finding minimum spring settings that maintain velocity consistency whilst maximising shot count—critical for competition shooters requiring extended shot strings.

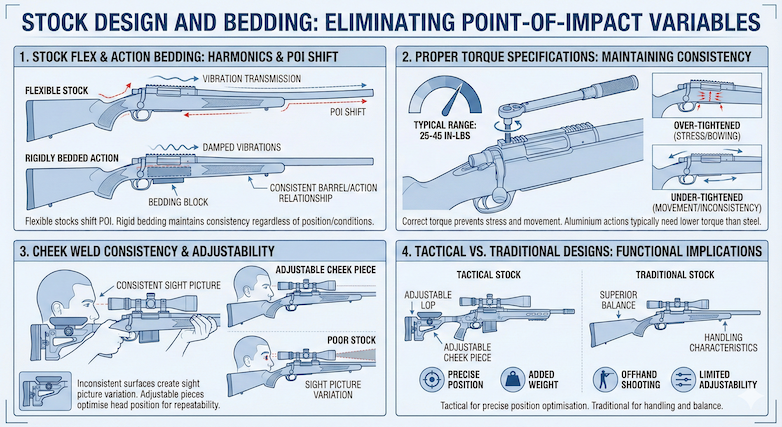

Stock Design and Bedding: Eliminating Point-of-Impact Variables

Stock flex and action bedding significantly affect barrel harmonics and accuracy consistency by transmitting vibrations between the action and barrel system. Flexible stocks can create point-of-impact shifts as shooting positions change, whilst improperly bedded actions may shift under recoil forces despite PCP systems’ minimal recoil characteristics. Professional-grade accuracy requires rigid action bedding that maintains consistent barrel/action relationships regardless of shooting position or environmental conditions.

Proper torque specifications for action screws maintain bedding consistency without inducing stress that can affect accuracy. Over-tightened action screws can bow actions and create stress patterns that shift zero, whilst under-tightened screws allow movement that destroys consistency. Most PCP rifles require action screw torques between 25-45 inch-pounds depending on stock material and action design, with aluminium actions typically requiring lower torques than steel actions.

Cheek weld consistency and stock design impact shooting technique repeatability more significantly than many shooters realise. Stocks with inconsistent cheek weld surfaces create sight picture variations that affect accuracy regardless of mechanical precision. Adjustable cheek pieces enable optimising head position for consistent sight picture, whilst poorly designed stocks may require aftermarket modifications to achieve professional-grade shooting position repeatability.

Tactical vs traditional stock designs offer functional implications for different shooting disciplines that go beyond aesthetics. Tactical stocks with adjustable length-of-pull and cheek pieces enable precise position optimisation but may add weight that affects field shooting applications. Traditional stocks prioritise handling characteristics and may offer superior balance for offhand shooting but typically provide limited adjustability for optimising shooting position consistency.

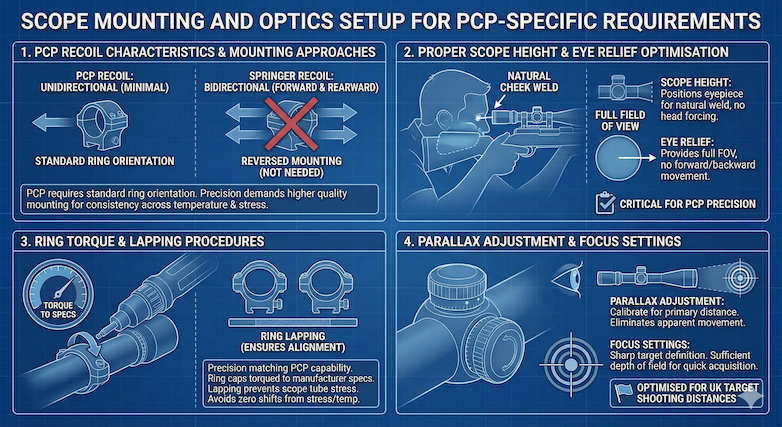

Scope Mounting and Optics Setup for PCP-Specific Requirements

PCP recoil characteristics require different scope mounting approaches than springer rifles due to the absence of dual-direction recoil forces. PCP rifles typically require standard scope ring orientation without the reversed mounting needed for springer applications, simplifying scope mounting whilst maintaining zero consistency. However, the precision capability of PCP systems demands higher quality scope mounting that maintains zero across temperature variations and mechanical stress.

Proper scope height and eye relief optimisation becomes more critical with PCP systems because their accuracy potential reveals sight picture inconsistencies that mediocre accuracy might mask. Scope height should position the eyepiece for natural cheek weld without forcing head position adjustments, whilst eye relief distance should provide full field of view without requiring forward/backward head movement to acquire sight picture.

Ring torque specifications and lapping procedures for maintaining zero require precision that matches PCP accuracy capability. Ring caps should be torqued to manufacturer specifications using quality torque drivers, whilst ring lapping may be necessary to ensure perfect alignment that prevents scope tube stress. Improperly mounted scopes can shift zero during temperature changes or mechanical stress, negating the consistency advantages that justify PCP investment.

Parallax adjustment and focus settings optimised for UK target shooting distances enable extracting maximum accuracy from PCP precision. Parallax adjustment should be calibrated for primary shooting distances to eliminate apparent target movement when head position varies slightly. Focus settings should provide sharp target definition at typical shooting distances whilst maintaining sufficient depth of field for quick target acquisition.

PCP Ownership in the UK: Power Limits, Licensing, and Responsible Shooting Practices

Understanding UK air rifle laws and compliance requirements enables responsible PCP air rifle UK ownership whilst maximising legal performance capabilities. Proper legal compliance builds confidence and community trust essential for maintaining UK shooting sports access.

UK Legal Requirements: 12 ft-lb Limit and Firearm Certificate Thresholds

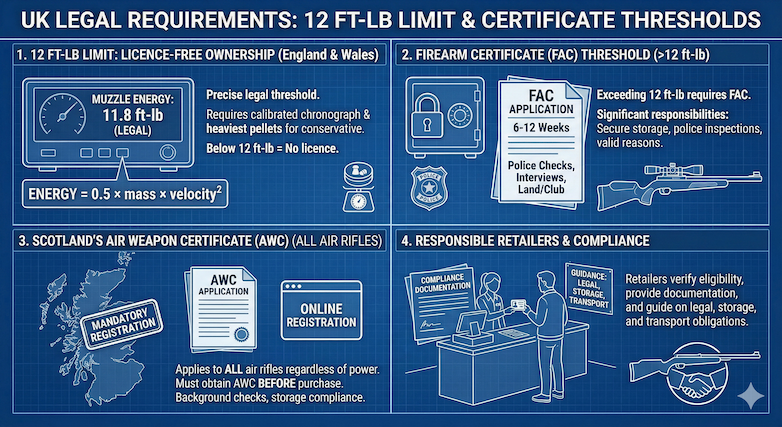

The 12 ft-lb muzzle energy limit for licence-free ownership in England and Wales represents a precise legal threshold that PCP owners must understand and verify. Muzzle energy calculation requires measuring projectile velocity with calibrated chronographs and using the heaviest available pellet weights to ensure conservative compliance measurements. The formula (Energy = 0.5 × mass × velocity²) with proper unit conversions provides legal energy calculations that courts recognise for compliance verification.

Firearm Certificate requirements apply to air rifles exceeding 12 ft-lb muzzle energy, creating significant additional responsibilities including secure storage requirements, police inspections, and valid reasons for ownership. The FAC application process typically requires 6-12 weeks and includes background checks, referee interviews, and shooting club membership or landowner permissions. FAC holders gain access to more powerful PCP rifles but accept substantial legal responsibilities that casual shooters should carefully consider.

Scotland’s Air Weapon Certificate requirement applies to all air rifles regardless of power level, making registration mandatory for any air weapon ownership. The AWC system requires online registration, basic background checks, and compliance with storage and transportation requirements. Scottish shooters must obtain AWC approval before purchasing any PCP air rifle, making advance planning essential for legal compliance.

Responsible retailers ensure compliance by verifying customer eligibility and providing documentation for legal ownership. Quality retailers maintain compliance records and provide guidance on legal requirements, storage obligations, and transportation regulations that protect both customers and the broader shooting community.

Power Testing and Chronograph Verification: Ensuring Your Rifle Stays Legal

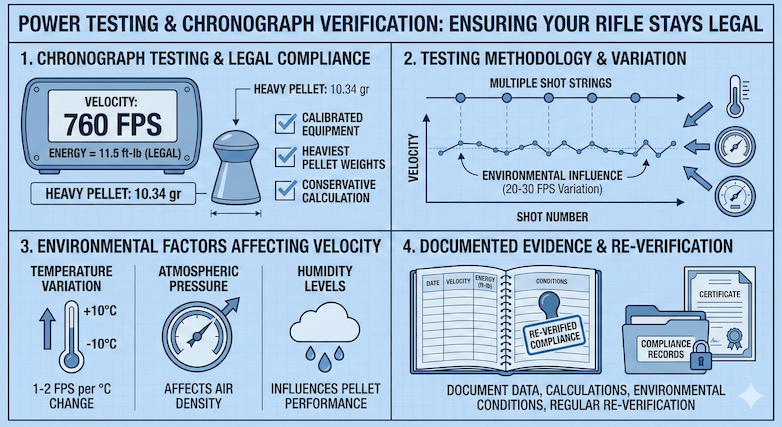

Chronograph testing represents essential verification for legal compliance, especially with adjustable PCP systems that can potentially exceed legal limits through modification. Proper testing methodology requires calibrated chronographs, consistent environmental conditions, and documentation that demonstrates conservative compliance margins. Testing should use the heaviest available pellet weights since energy calculations favour heavier projectiles for conservative legal compliance.

Proper testing methodology involves multiple shot strings across different environmental conditions to account for velocity variations that might affect energy output. Temperature, atmospheric pressure, and humidity can influence velocities by 20-30 FPS, potentially affecting energy calculations near legal limits. Conservative testing approaches use worst-case environmental conditions and multiple measurement sessions to ensure consistent legal compliance.

Environmental factors affecting velocity readings include temperature variations that can change velocities by 1-2 FPS per degree Celsius, atmospheric pressure changes that affect air density, and humidity levels that may influence pellet performance. Understanding these factors enables accurate testing and prevents accidental non-compliance due to environmental variations affecting rifle performance.

Maintaining documented evidence of compliance provides protection for responsible owners and supports the broader shooting community’s legal status. Documentation should include chronograph data with environmental conditions, energy calculations with safety margins, and regular re-verification to demonstrate ongoing compliance. This documentation protects individual owners and supports community efforts to maintain legal shooting access.

Safe Storage, Transportation, and Shooting Location Requirements

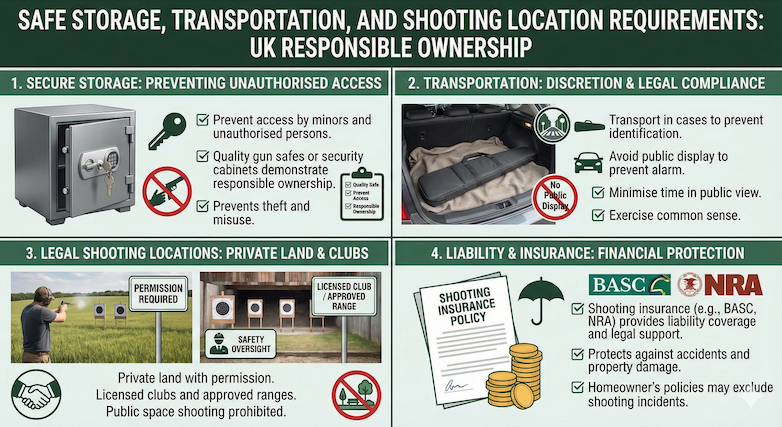

UK requirements for secure air rifle storage emphasise preventing access by unauthorised persons, particularly minors. Whilst specific storage requirements for sub-12 ft-lb air rifles are less stringent than FAC requirements, responsible ownership includes secure storage that prevents theft and unauthorised use. Quality gun safes or security cabinets provide appropriate storage whilst demonstrating responsible ownership that supports continued legal access.

Transportation regulations require discretion and common sense to avoid public concerns whilst maintaining legal compliance. Air rifles should be transported in cases that prevent identification and avoid public display that might cause alarm. Vehicle transportation should minimise time spent in public view and avoid locations where firearms are prohibited, even though legal air rifles don’t require the same precautions as firearms.

Legal shooting locations include private land with appropriate permissions, licensed shooting clubs, and approved ranges that provide safe shooting environments. Shooting on private land requires landowner permission and consideration of neighbours, whilst club shooting provides structured environments with safety oversight. Public space shooting is generally prohibited and risks legal consequences even with legal air rifles.

Liability considerations and insurance options provide financial protection for UK air rifle owners who understand the potential consequences of accidents or property damage. Shooting insurance through organisations like BASC or NRA provides liability coverage and legal support, whilst homeowner’s insurance policies may exclude shooting-related incidents. Understanding liability exposure enables appropriate insurance coverage that protects both individuals and the broader shooting community.

Real-World PCP Performance: Case Studies from UK Precision Shooters

Validating technical concepts with concrete examples demonstrates how proper PCP air rifle selection and optimisation deliver measurable accuracy improvements for serious UK shooters pursuing professional-grade results.

Case Study: From 2-Inch Springer Groups to Half-MOA PCP Precision

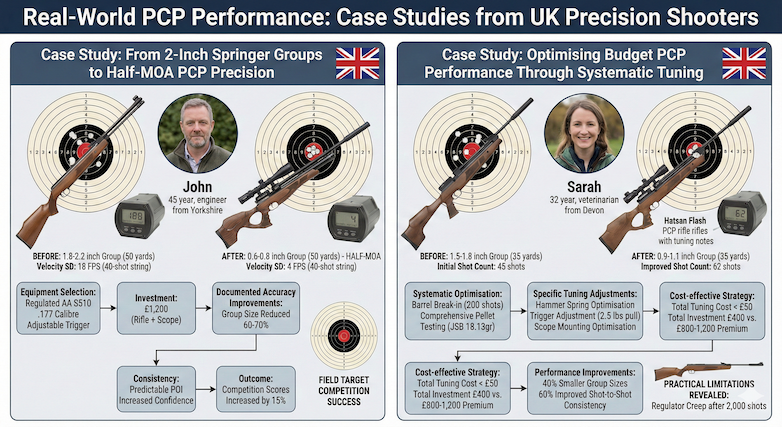

John, a 45-year-old engineer from Yorkshire, exemplifies the precision improvements available when transitioning from quality springer to regulated PCP rifle technology. Starting with a well-maintained Weihrauch HW97K that consistently delivered 1.8-2.2 inch groups at 50 yards, John sought accuracy improvements for field target competition where precision directly impacts competitive success.

Equipment selection focused on a regulated Air Arms S510 in .177 calibre, chosen for its proven consistency, adjustable trigger, and suitability for field target applications within UK legal limits. The selection process emphasised technical specifications including regulator stability, barrel quality, and trigger adjustability rather than marketing claims or aesthetic preferences. Total investment including scope and accessories reached £1,200—a significant commitment requiring measurable performance improvements for justification.

Documented accuracy improvements included group size reductions from 2-inch springer groups to 0.6-0.8 inch groups at 50 yards following systematic ammunition testing and rifle optimisation. Chronograph data showed velocity standard deviations improving from 18 FPS with the springer to 4 FPS with the regulated PCP system across 40-shot strings. This consistency translated to predictable point-of-impact and increased confidence on challenging field target courses where precision determines competitive success.

Investment cost analysis after 12 months revealed the PCP system’s value through improved competition performance and shooting enjoyment. Competition scores increased by an average of 15% due to improved accuracy and consistency, whilst shooting session satisfaction increased significantly due to predictable performance. The total cost per improved performance unit justified the investment for a serious competitor prioritising measurable accuracy improvements.

Case Study: Optimising Budget PCP Performance Through Systematic Tuning

Sarah, a 32-year-old veterinarian from Devon, demonstrates how systematic optimisation can extract professional-grade performance from budget PCP air rifle UK platforms without requiring complete equipment replacement. Starting with a Hatsan Flash in .22 calibre purchased for £280, Sarah’s methodical approach showed significant accuracy improvements through proper setup and ammunition testing.

Systematic barrel break-in and ammunition testing revealed the rifle’s accuracy potential once proper procedures were followed. Initial groups measured 1.5-1.8 inches at 35 yards, but systematic break-in over 200 shots and comprehensive pellet testing identified JSB 18.13-grain pellets that tightened groups to 0.9-1.1 inches. The process required patience and systematic documentation but demonstrated that budget rifles could deliver competitive accuracy with proper optimisation.

Specific tuning adjustments included hammer spring optimisation that improved shot count from 45 to 62 shots whilst maintaining velocity consistency, trigger adjustment that reduced pull weight to 2.5 pounds for improved precision, and scope mounting optimisation that eliminated zero shift during temperature changes. These adjustments cost under £50 in tools and accessories but delivered measurable consistency improvements.

Cost-effective optimisation strategies proved that systematic attention to details could deliver professional-grade results without premium equipment investment. Total optimisation costs including ammunition testing reached £120, bringing the total investment to £400 compared to £800-1,200 for premium alternatives. Performance improvements included 40% smaller group sizes and 60% improved shot-to-shot consistency—demonstrating that technique and knowledge often matter more than equipment cost.

The optimisation process revealed practical limitations of budget platforms including regulator creep after 2,000 shots and trigger components requiring replacement after heavy use. However, the accuracy improvements and learning experience provided excellent value whilst building knowledge for future equipment decisions. Sarah’s systematic approach proved that dedicated shooters could achieve competitive accuracy across price ranges through proper understanding of PCP optimisation principles.

Conclusion: Mastering PCP Technology for UK Precision Excellence

Mastering PCP air rifle technology means understanding the engineering principles that separate consistent half-MOA precision from frustrating accuracy variations. From regulator dynamics and barrel harmonics to systematic ammunition testing and proper tuning, the technical knowledge in this guide provides the foundation serious UK precision shooters need to make informed equipment decisions and extract maximum accuracy from PCP air rifle UK platforms. Whether you’re evaluating your first PCP purchase or optimising an existing system, these engineering principles and practical techniques enable professional-grade results within UK legal limits.

The transition from spring-piston to PCP air rifle accuracy represents more than equipment upgrading—it requires understanding pneumatic systems, regulator behaviour, and optimisation techniques that transform shooting from hoping for good groups to confidently expecting tight clusters. The consistency advantages of properly configured PCP systems create shooting experiences where technique development matters more than managing equipment variables, enabling focus on fundamental marksmanship skills that deliver competitive advantages.

Regulated PCP rifles offer the ultimate consistency platform for serious UK precision shooters, but unregulated systems can deliver competitive accuracy when properly understood and optimised. The key lies in matching equipment capabilities to shooting requirements whilst understanding the technical principles that enable extracting maximum performance from any quality PCP platform within budget constraints.

The engineering knowledge you’ve gained here transforms equipment selection from marketing-driven guesswork to informed technical decisions based on proven performance principles. Whether pursuing field target competition excellence or simply demanding the precision that makes every shot count, mastering PCP technology enables the consistency and accuracy that separates serious shooters from casual plinkers.

Ready to experience the precision advantages that make PCP technology the choice of serious UK target shooters who demand professional-grade results? The technical foundation is now in place—it’s time to apply this knowledge to achieve the sub-MOA consistency that transforms your shooting from acceptable to exceptional.

Watch this video for more information on PCP Air Rifles: